Industry Press Release: Automotive Air Filter Maintenance Guide – Key Measures to Extend Engine Lifespan

May 30, 2024

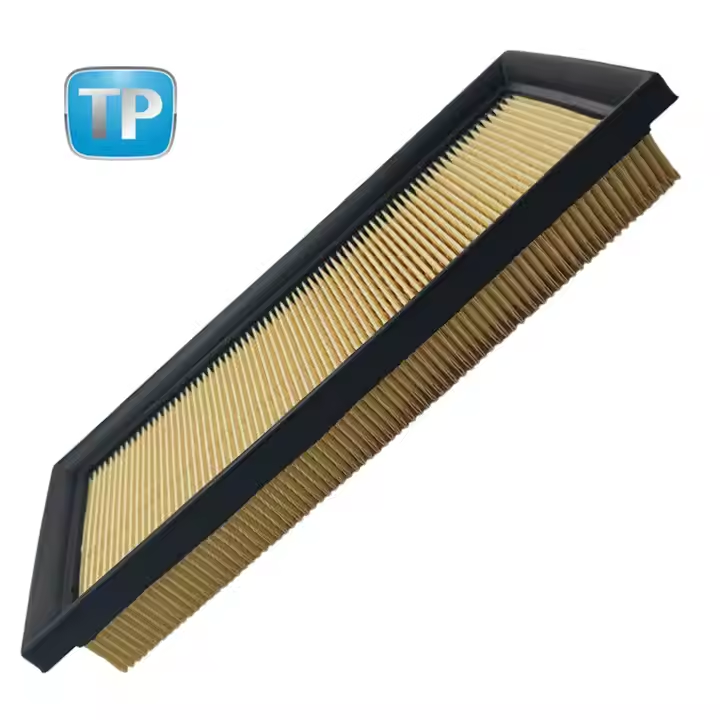

With the continuous growth of global vehicle ownership, engine maintenance has become a core concern for car owners and the industry. As the "first line of defense" for engines, the regular replacement and quality selection of air filters directly impact vehicle performance, fuel efficiency, and longevity. Recently, industry experts reiterated the importance of scientific air filter maintenance and released updated guidelines to help owners and service providers optimize maintenance strategies.

According to the latest Global Automotive Air Filter Market Report, the market size reached $4.5 billion in 2023 and is projected to grow at an annual rate of 4.5% over the next five years. This growth stems not only from increased vehicle production and sales but also from heightened consumer awareness of engine protection and innovations in filter technology.

Leading manufacturers are accelerating R&D in high-efficiency filtration materials, such as nanofiber layers and multi-stage filtration systems, to address complex environmental challenges. Meanwhile, stricter environmental regulations are driving the industry toward sustainability, with eco-friendly products like washable filters and biodegradable materials gradually entering the market.

Industry consensus emphasizes a "dual-dimensional" approach based on mileage and environment:

Standard Recommendation: Replace every 15,000 kilometers or annually, whichever comes first.

Harsh Conditions: In dusty, highly polluted, or humid areas, shorten replacement intervals to 10,000 kilometers or every six months.

Research by the North American Automobile Association (AAA) indicates that overdue filters may reduce engine air intake efficiency by 20%, increase fuel consumption by 10%, and significantly raise the risk of cylinder wear from particulate matter.

Reduced Power: Sluggish acceleration or difficulty climbing hills signals restricted airflow due to clogged filters.

Increased Fuel Consumption: Imbalanced air-fuel ratios force the ECU to inject more fuel, potentially spiking consumption by over 15%.

Abnormal Noises: Insufficient airflow triggers engine knocking or unusual sounds.

Warning Lights: MAF sensors in some models may activate the "Check Engine" alert.

Despite widespread recognition of air filter importance, two major pain points persist:

Counterfeit Products: Non-compliant filters exhibit less than 30% filtration efficiency and may release harmful substances. Experts recommend ISO-certified products and thorough manufacturer vetting.

Owner Misconceptions: Approximately 40% of owners believe "visually clean filters require no replacement," overlooking microscopic pore blockages.

In response, the International Society of Automotive Engineers (SAE) has introduced standardized testing protocols requiring manufacturers to label filtration efficiency (≥99.5%), dust-holding capacity, and humidity resistance to enhance market transparency.

With IoT integration, smart filters embedded with pressure sensors now monitor clogging in real time and alert users via vehicle systems. Additionally, global supply chain restructuring is boosting efficiency—leading companies leverage cross-border production hubs and automated lines to achieve 48-hour global logistics response, stabilizing end-user pricing.

"Air filters are not standalone components; they require coordinated maintenance with oil and fuel systems," advised Hans Müller, a TÜV-certified engineer from Germany. "Automakers, suppliers, and service networks should collaborate on tailored maintenance packages, using data models to optimize replacement cycles for specific vehicle models."